Maximieren Sie Output und Erfolg

Möchten Sie Ihren Betrieb auf das nächste Level bringen? Unsere Dienstleistungen und Softwaretools bieten Ihnen die perfekte Kombination aus Analyse, Optimierung, Implementierung und Profitabilität.

Analysieren

You can only improve what you’ve taken the time to understand.

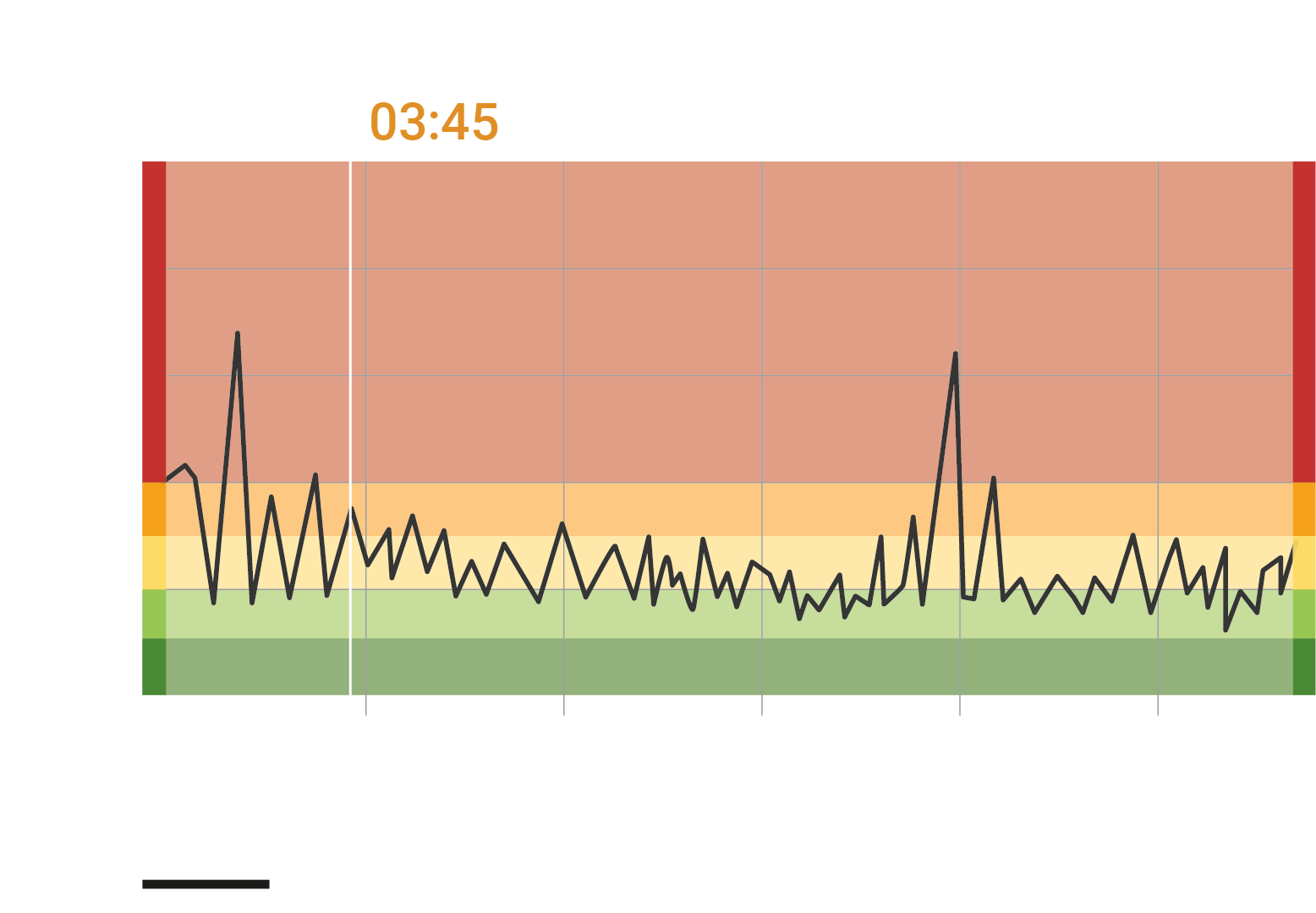

Wir beginnen mit einer gründlichen Analyse der aktuellen Prozesse und Abläufe. Unsere ExpertInnen führen eine eingehende Analyse aller Material- und Energieflüsse durch, um potenzielle Bereiche für Verbesserungen zu identifizieren.

Optimieren

Use what you have, get what you need.

Nach der eingehenden Analyse gehen wir einen Schritt weiter, um Ihre Prozessabläufe zu optimieren. Wir entwickeln maßgeschneiderte (Software)Lösungen, die auf Ihre spezifischen Anforderungen zugeschnitten sind, um Effizienzsteigerungen und Kosteneinsparungen zu erreichen.

Implementieren

Use our Tools and improve your System.

Die besten Pläne sind wertlos, wenn sie nicht ordnungsgemäß umgesetzt werden. Unsere ExpertInnen unterstützen Sie bei der nahtlosen Implementierung der vorgeschlagenen Maßnahmen. Wir bieten umfassende Unterstützung, um sicherzustellen, dass die Änderungen erfolgreich umgesetzt werden.

Profit

Profit from our know-how:

Der letzte und wichtigste Schritt ist der Erfolg, den Sie durch unsere Dienstleistungen erzielen. Mit unseren (Software)Lösungen können Sie einerseits die Vorteile eines optimierten Prozessablaufs voll ausschöpfen und eine nachhaltige Profitabilität sicherstellen, und andererseits den erzielten Erfolg quantifizieren.

PROFIT DURCH WISSEN!

Nutzen Sie die Chance Ihr Unternehmen zu transformieren und Ihre Erfolgschancen zu maximieren. Kontaktieren Sie uns, um mehr zu erfahren. Wir helfen Ihnen, zu analysieren, zu optimieren, zu implementieren und zu profitieren!

Wer sind wir?

Das Team von VIRWa verfügt über mehr als 40 Jahre Erfahrung im Bereich Abfall- und Ressourcenmanagement. Ein wesentlicher Schwerpunkt neuerer Arbeiten liegt auf einer systembasierten Optimierung von Abfall- und Ressourcensystemen unter Berücksichtigung von Umweltauswirkungen (Klimawandel, Rohstoffverknappung, …) und Kosten.

Letztlich geht es bei jedem Projekt darum, den kosteneffizientesten Weg zu finden, um die Ziele der Abfallwirtschaft (Schutz von Mensch und Umwelt) zu erreichen und gleichzeitig die SDGs (Sustainable Development Goals) zu verfolgen.

Unsere Expertise

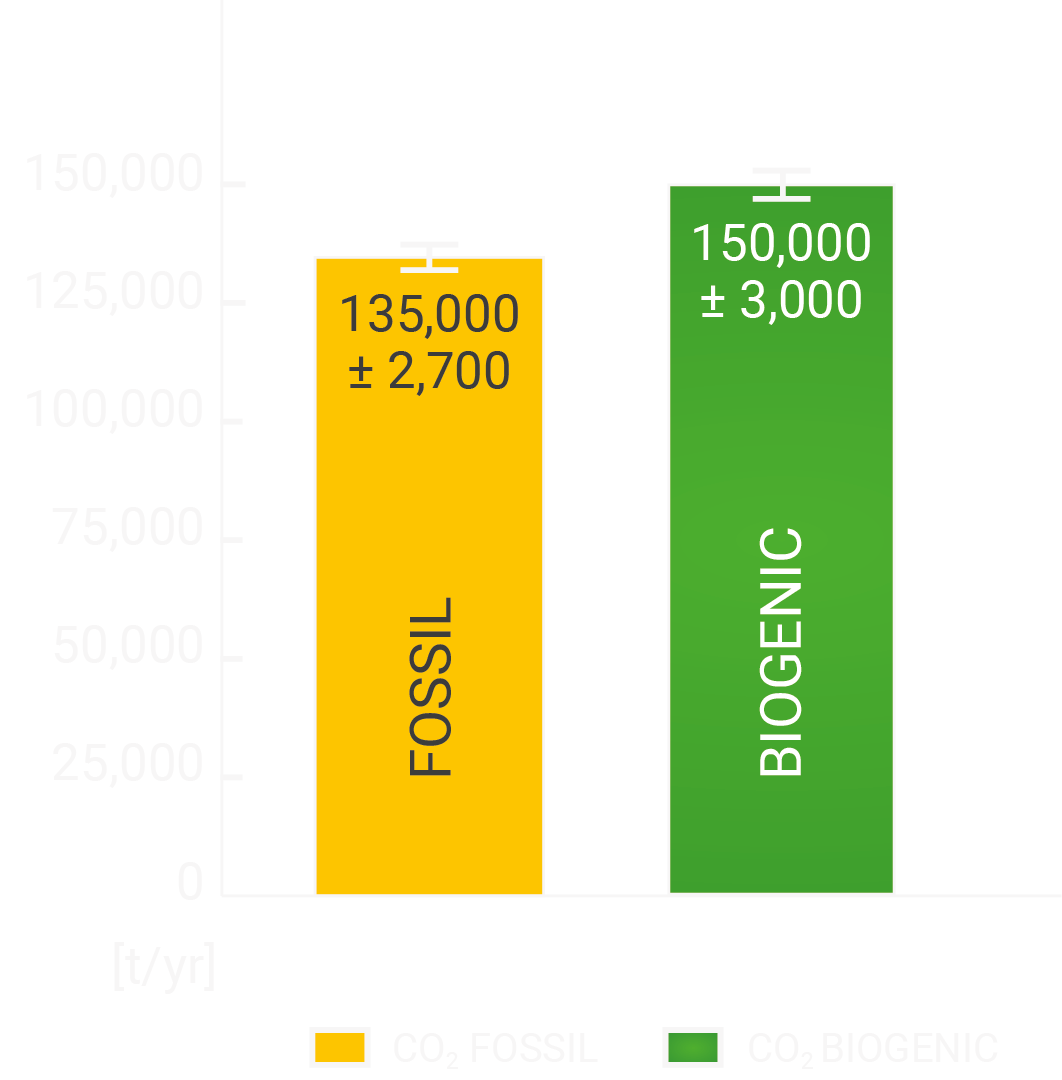

Analyse von Abfallprozessen und -systemen, Abfallwirtschaftsplanung, Bewertung von Treibhausgasemissionen (auf verschiedenen Ebenen), Analyse und Optimierung des Betriebs von Müllverbrennungsanlagen, Analyse von Ersatzbrennstoffen, Design und Bewertung von Deponiebelüftungsprojekten, Bewertung der Deponienachsorge, Industrieabfallmanagement (Industrial Symbiose), Analyse von Stoffkreisläufen (z. B. Stahl oder Kunststoffe), Materialflussanalysen von Wert- und Schadstoffen (z. B. Schwermetalle, POPs).

In Summe haben unsere Experten (Johann Fellner und Therese Schwarzböck) mehr als 500 Berichte und wissenschaftliche Puplikationen veröffentlicht.

PARTNER & KUNDEN